While the art of baking remains an age-old tradition, modern bakeries are increasingly embracing technological advancements to revolutionise and streamline operations, improving efficiency and quality. One such innovation that has been transforming the bakery industry is the integration of DTA heavy movers.

Read MoreIn November 2023 at the Lab Innovations and Advanced Engineering show, Applied Integration showcased their innovative robot application featuring the ABB GoFa robot arm and the Cambrian vision system.

Read MoreThe shipbuilding industry has witnessed significant technological advancements over the years, transforming the way ships are being constructed. A ground-breaking innovation that has taken the industry by storm are DTA’s heavy duty transporters.

Read MoreEstablished in Stokesley, North Yorkshire, in 2005, Applied Integration UK Ltd (AIUK) has been a prominent supplier to the world's leading defence markets since 2007. Our expertise lies in delivering cutting-edge complex control systems, software integration, and panel build services.

Read MoreIn today's fast-paced world, logistics and warehousing industries face increasing pressure to optimise operations, reduce costs, and enhance efficiency. Automation has emerged as a transformative solution to meet these challenges, and autonomous mobile robots (AMRs) have taken centre stage. Amongst these ground-breaking technologies is the A-MATE® Counter.

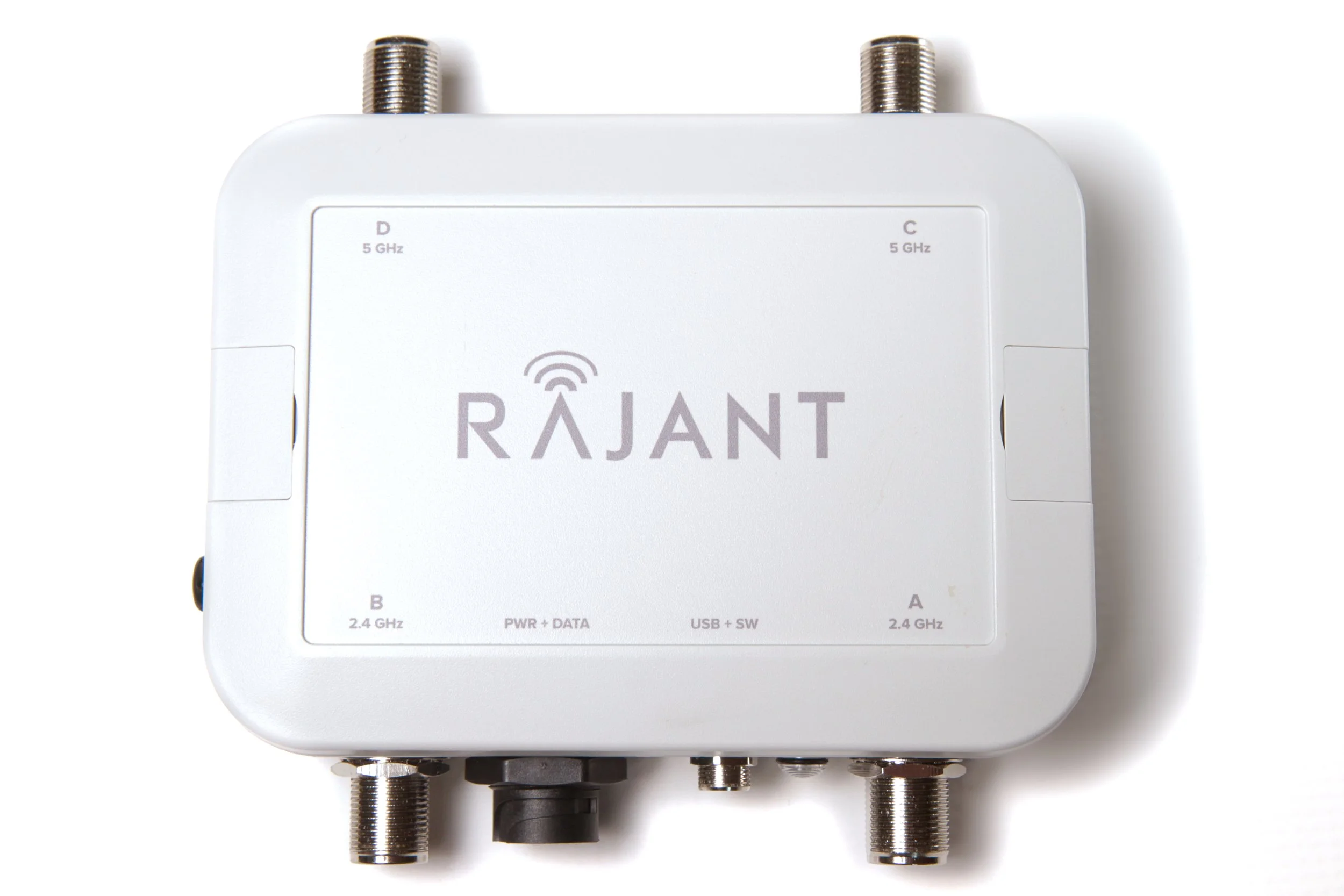

Read MoreThe Defence sector continually faces the complexities of maintaining broadband connectivity, especially in remote and often hostile environments. However, a wireless military network is critical for tactical strategies, situation awareness, convoy communications, and, most importantly, saving lives.

Read MoreBy introducing Rajant Kinetic Mesh technology, it enables a robust wireless solution engineered to ensure wireless connectivity is simple, instantaneous, and fail proof.

Read MoreThe A-MATE®, manufactured by K.Hartwall, is an intelligent mobile robot designed to transport logistic units such as pallets and containers around production and logistic environments without the need for an on-board operator.

Read MoreRajant provides resilient coverage port wide without any drop offs. Rajant wireless network nodes are fully mobile and work peer-to-peer. Rajant nodes work together connect and communicate around port obstructions maintaining mission-critical coverage.

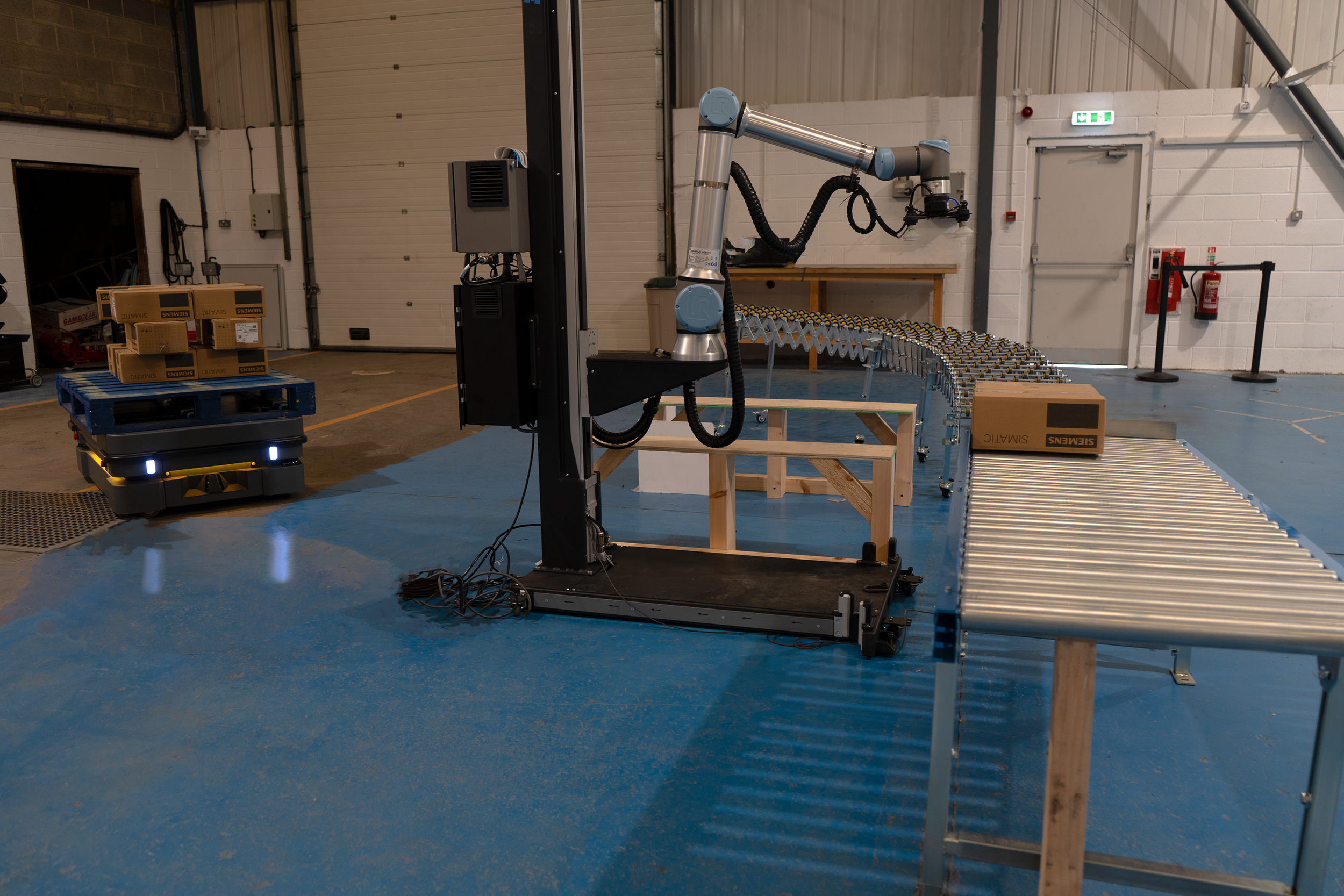

Read MoreMany logistics and warehouse companies are adopting robotic palletizing solutions, improving their time to market and cost effectiveness. Palletizing has the potential to free up employees for higher value-added tasks whilst dealing with labour shortages.

Read MoreRajant Kinetic Mesh helps automated and autonomous warehouses maintain the continuous mobile connectivity that is needed 24/7. Busy warehouses must operate at peak efficiency to keep up with growing demands which is why many are adopting robotics and automation.

Read MoreDo you have a palletizing operation which requires automation? Many logistics and warehouse companies especially within the food and beverage markets, have the potential to increase their productivity and free up their employees for higher value-added tasks by adopting Robotic Palletizing Solutions. Implementing this solution will make a big difference in labour, time to market and cost effectiveness.

Read MoreDo you struggle with achieving consistent and reliable connectivity across your full site? While there are no shortages of connectivity and network options for companies involved in military, mining, ports, rail, oil & gas, petrochemical plants, public safety, agriculture, and warehouse & factory automation, all fall short of effectively connecting a growing and moving infrastructure.

Read MoreApplied Integration are excited to announce their partnership with Rajant Corporation, a broadband communications technology company that invented Kinetic Mesh® networking, a fully mobile wireless mesh network connectivity that is simple, instantaneous, and fail-proof in any application.

Read MoreOne of Applied Integration’s growth areas is creating simulation models or ‘digital twins’. There are three main stages when it comes to digital simulation/digital twins; Demonstration, System Simulation and System Emulation.

Read MoreHeavy payload transport and positioning is often a specialist, time consuming, labour intensive, and a potentially hazardous business. Components to be manoeuvred through the production process can be physically large or present awkward dimensions. Each may require precise positioning in very challenging environmental conditions. Moving such items requires experience and skill.

Read MoreOur software engineers have created a remote controller for the Techman Robot Arm and the Radwag Analytical Balance. It is responsible for communicating directly to the equipment as well as instructing them to perform tasks in the correct sequential order.

Read MoreACOPOS 6D, a new solution to smart manufacturing from B&R Industrial Automation. Magnetic levitating shuttles sized at 240 x 240mm float over the surface of electromagnetic segments moving individual products of payloads of up to 14kg freely through the machine, eliminating standard transport systems.

Read MoreAutoguide’s AMRs provide a modular base that can be configured as a tow tractor or pallet stacker and can manage payloads of up to 6.8 tons. The AMRs are guided by laser, radar and environment mapping technologies, meaning navigation without the need to maintain navigational aids such as tapes, RFID tags and reflectors enabling the AMR to quickly change routes and duties to match the changing needs of the organisation.

Read MoreSocial distancing makes it difficult to get two or more people interacting and working closely on assembly tasks, consequently the tasks take longer to complete. The level of impact: An increase of 30%+ in time required to complete an assembly stage.

Read More