Collaborative Robots

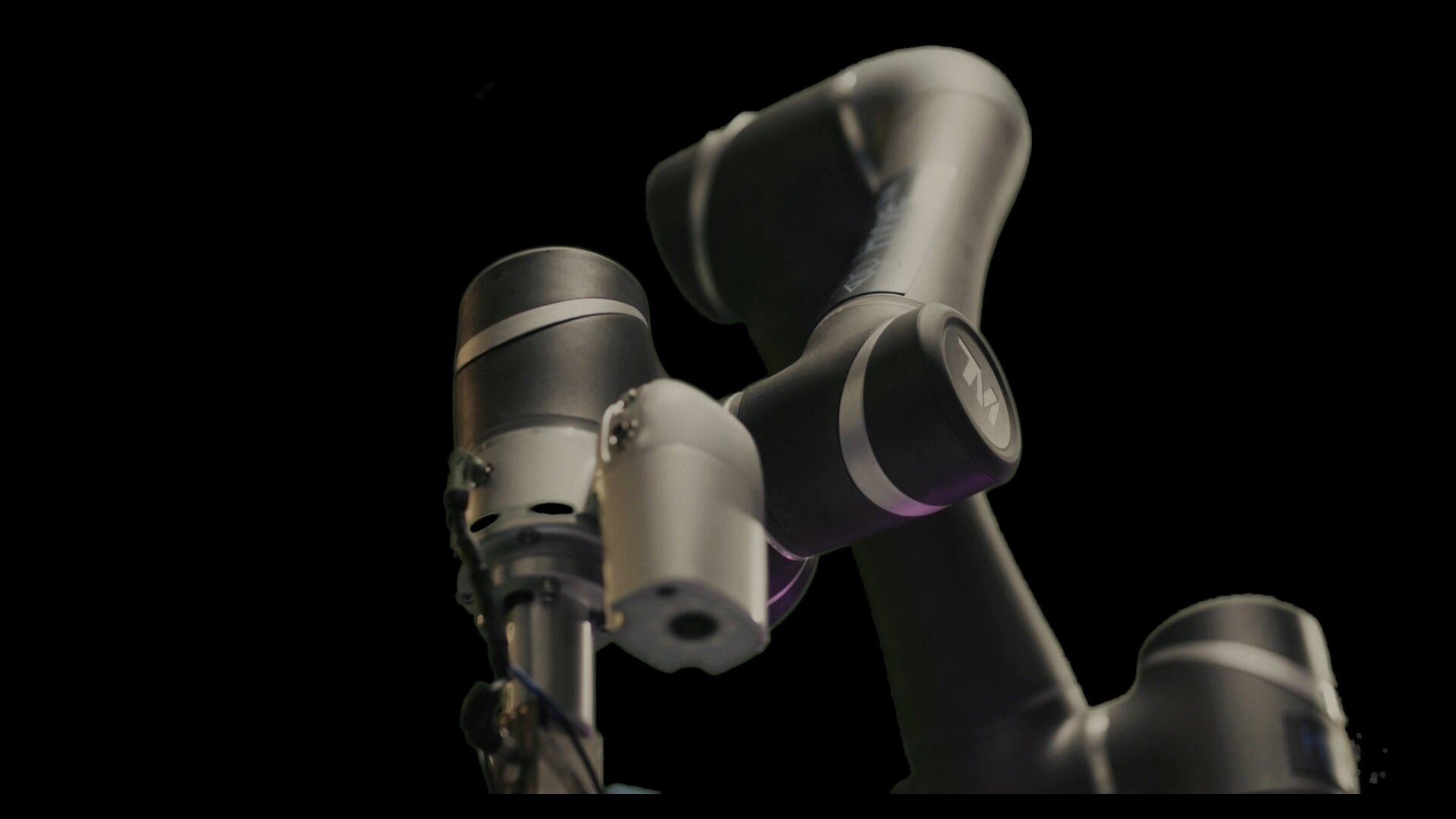

Are you ready for the future of automation, where human and machines work in harmony? The new range of collaborative robots (cobots) are safer, simple to program and easier to integrate within your automation systems, representing big steps towards intelligent manufacturing.

Intelligent, agile robotic arms offer a high degree of agility, can work collaboratively with humans and are ideal for executing pick/place/assembly, quality inspection tasks in a highly repeatable and re-produceable manner.

Cobots are versatile and adaptable to numerous applications typical use cases for Cobots include:

· Machine tending (item transfers)

· Packing (components, foods)

· Dispensing (liquids)

· Polishing/Finishing

· Assembly tasks

· Quality Inspection

· Combined with Mobile robots for pick/place transfer and transport.

With the ever rapid growing markets and new features available, from built-in vision, precision, ease of programming, flexible and safe deployment, Applied Integration UK are here to help you select the correct solutions, boosting your productivity, increasing quality and gaining a competitive advantage.

Maximise the potential, achieve your productivity goals and get immediate returns on your investment:

There are numerous Cobot systems available offering a wide range of capabilities:

Positional accuracy, stability, Payload lift capacity, Reach, Cost points and plug and play EOAT options.

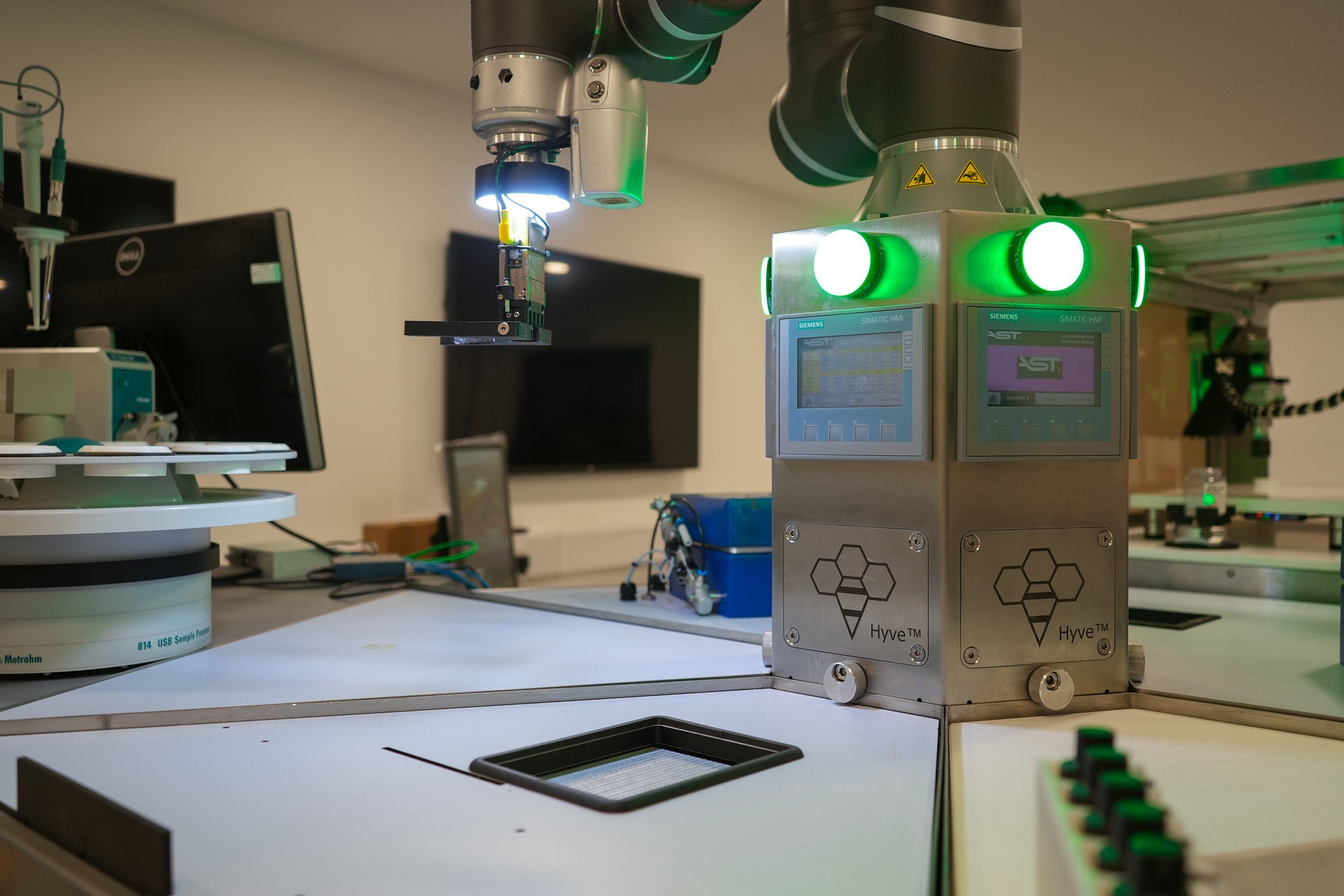

A stand-alone Cobot performs the pick operation, however it is typically only part of the solution required to fulfil workflow task and maximise the potential. For example, picking/sorting randomly placed items will require an integrated solution that combines multiple third-party technologies such as:

Intelligent vision systems for target object identification/selection/manipulation

Safety interlocks

Bespoke to application graphical interfaces for reporting/user interaction etc.

Bespoke EOAT devices

Picking random placed object for a bin, place

Pick object and perform a sequence of operations with EOAT changes etc